A comprehensive guide to reinventing companies

Mastering the

Transformation Journey

2015June 2016

THINK

ACT

BEYOND MAINSTREAM

Building Europe's road to "Construction 4.0"

Digitization in the

construction industry

THE BIG

3

2 THINK ACT

Digitization in the construction industry

93%

of construction industry players agree that digitization

will affect every process.

Page 3

<6%

of construction companies make full use

of digital planning tools.

Page 13

100%

of building materials firms believe they have not yet

exhausted their digital potential.

Page 7

TREND

RADAR

for the German

construction

industry

P. 9

THINK ACT

Digitization in the construction industry

3

Digitization is about businesses encountering connect-

ed systems at every link in the value chain. It is about

working with tools and practices based on information

and communication technology. This understanding

is changing the role of digital technologies. They are no

longer mere tools to help companies do the same

things a bit better. Instead, they fundamentally change

the way business is done. Digitization permeates every

part of every company: multinationals and midcaps,

all-rounders and specialists alike.

A glance at other industries shows the extent to

which digitization is turning proven and familiar prac-

tices on their head. In the music industry, for example,

digital offerings already account for 46% of total sales

worldwide. On this kind of scale, it is certainly reason-

able to speak of a revolution – especially as one has to

assume that digitization has replaced legacy business

models in their entirety.

A large majority of players in the construction in-

dustry today recognize how digitization is affecting ev-

ery part of their business too. According to one study

by the Association of German Chambers of Commerce

and Industry (DIHK), 93% of companies agree that dig-

itization will influence every one of their processes.

This perception places construction on a par with re-

tail and only just behind both the manufacturing in-

dustry and service providers – despite the fact that the

needs and approaches of different actors vary very con-

siderably. Producers of building materials tend to fo-

cus more on digitizing production and distribution

(along the lines of Industry 4.0 and the design of the

customer journey, for example). By contrast, construc-

tion companies concentrate primarily on the digitiza-

tion of planning, construction and logistics (building

information modeling – BIM – and the connected

"building site 4.0"). For their part, building material

traders add a strong focus on digital sales (online trad-

ing) to their logistical considerations.

Clearly, the industry is aware of the importance of

the megatrend toward digitization. The problem lies

rather with implementation. This is the finding of an

exclusive Roland Berger management survey, above all

among construction firms and their suppliers in Ger-

many, Austria and Switzerland. The results of the sur-

vey paint an up-to-date picture of how industry players

rate the potential of digitization and the extent to

which implementation has progressed. We call the pic-

ture that emerges "Construction 4.0".

1

There is no alternative

to digitization. Even on

the building site.

Construction needs to

catch up.

1 Although building material traders were not included in the survey,

this paper occasionally touches on the impact of digitization on this

segment and the opportunities it affords.

THINK ACT

Digitization in the construction industry

4

ed to nearly 40 companies of all sizes (whose business

focuses on construction and building supplies). The

respondent firms reflect the following revenue break-

down:

> Less than EUR 10 million: 13%

> EUR 10 million to EUR 100 million: 26%

> EUR 100 million to EUR 500 million: 32%

> EUR 500 million to EUR 1 billion: 6%

> More than EUR 1 billion: 23%

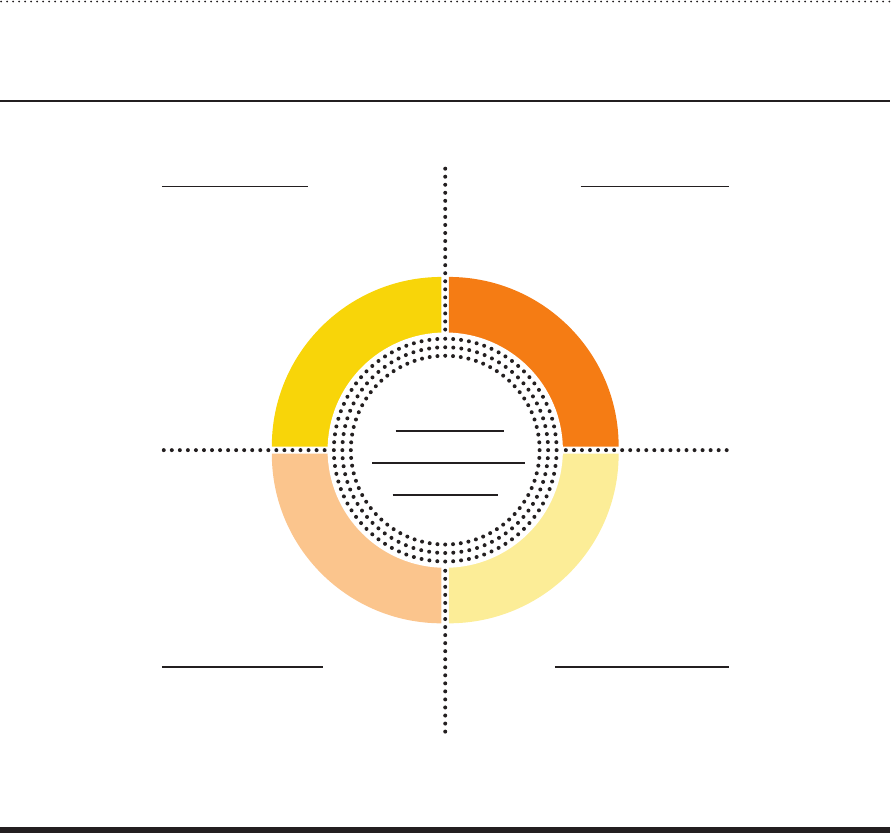

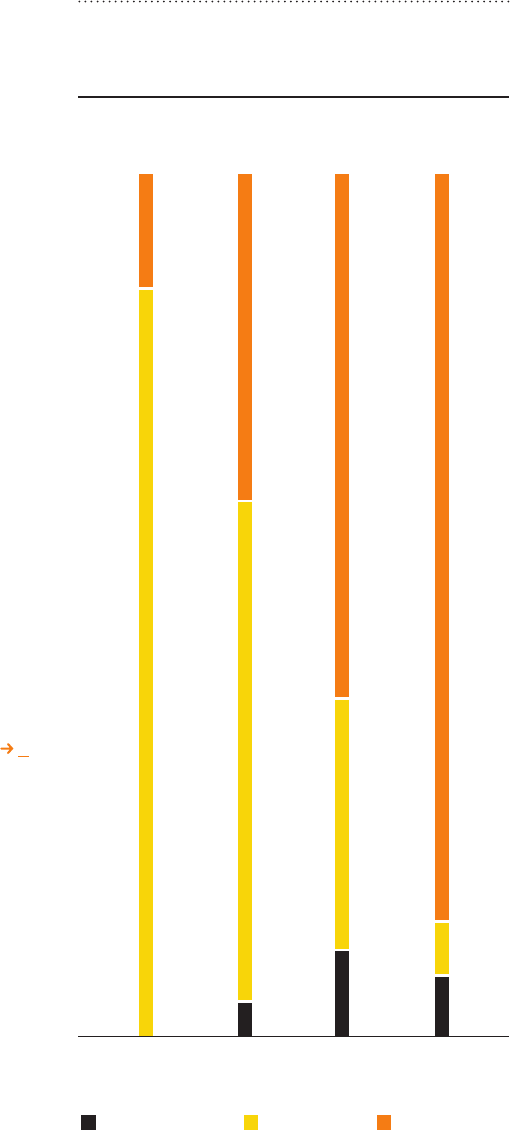

To clearly show how the potential of digitization is rat-

ed across individual divisions, departments and func-

tions, we split it into four key areas: digital data, digital

access, automation and connectivity. Digital data cov-

ers the electronic collection and analysis of data to

gain fresh insights into every link in the value chain

and then put these insights to good use. Automation

groups together those new technologies that create au-

tonomous, self-organizing systems. Digital access de-

scribes the potential afforded by mobile access to the

internet and internal networks. Lastly, connectivity

explores the possibilities to link up and synchronize

hitherto separate activities.

A

One crucial factor regarding the vast potential of

digitization is that each of these four keys can be

turned at every link in the value chain. For players in

the construction industry, the value chain breaks down

into the following links:

Digitization gives players in the construction industry

ways to improve their productivity. While other indus-

tries are already benefiting – along the entire value

chain – construction still lags behind. Few players have

yet turned to the potential of digitization as a way to

resolve this problem.

Such hesitant implementation is all the more sur-

prising when one considers the trend in productivity in

the construction industry. Over the past ten years, pro-

ductivity in Germany has edged up by a meager 4.1%.

By comparison, productivity across the whole of the

German economy has increased by 11% in the same

period. The gap between construction and industry is

particularly wide: Manufacturing has seen productivity

rise by 34.1% on average over the past decade, against

a gain of 27.1% for the whole of the secondary sector.

In other European countries, productivity in the con-

struction sector has actually declined – by 5% per an-

num in Italy and Spain in the period from 2010 through

2015. France just about managed a 1% per annum gain

in the same period.

To find out more about where digitization is at in

the world of construction, we conducted a survey of

top management in the construction and supply in-

dustry in Germany, Austria and Switzerland. Our sur-

vey also included in-depth interviews that let us drill

down into specific approaches and problem areas. To

capture the mood of the industry as a whole, we talk-

Four keys to unleash the

potential of digitization

in the European

construction industry.

THINK ACT

Digitization in the construction industry

5

DIGITAL DATA

Electronic collection and analysis

of data

AUTOMATION

Use of new technologies to create

autonomous, self-organizing

systems

CONNECTIVITY

Connection and synchronization

of hitherto separate activities

DIGITAL ACCESS

Mobile access to the internet and

internal networks

Source: Roland Berger

FOUR KEYS TO THE DIGITAL TRANSFORMATION

Four key aspects are useful to get digitization up and running.

Their importance extends across every link in the value chain.

A

> Logistics: Flow of goods, storage and transportation

> Procurement: Purchasing, supplier management and

supplier evaluation

> Production/construction: Production and quality

management

> Marketing/sales: Sales/dealer management

> After sales/end-customer marketing: Pull marketing,

user support and services

The precise content of each link in the value chain var-

ies from player to player. While suppliers of building

materials focus primarily on production, construction

companies naturally concentrate more on completing

building projects. Building material traders in turn ap-

ply themselves to procurement and sales, with a corre-

sponding focus on logistical services.

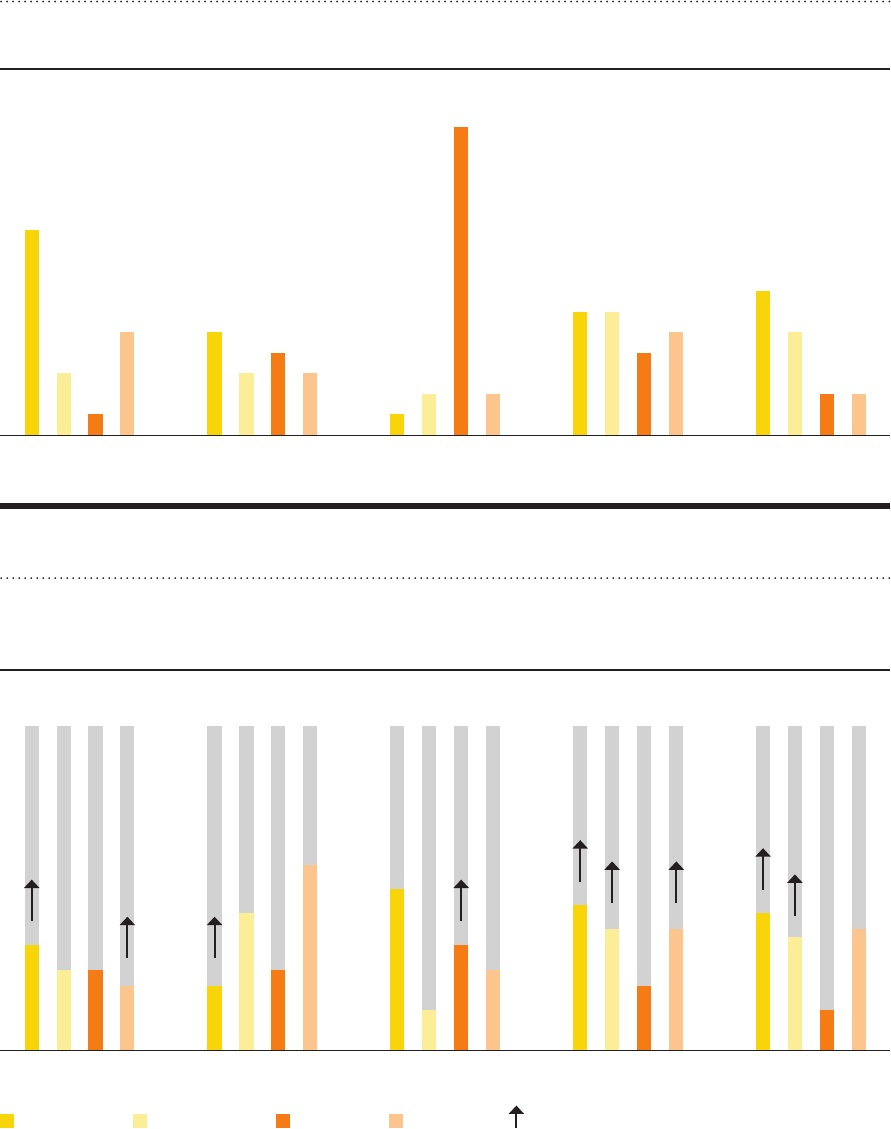

The findings of our survey of top management

across players in the construction industry reveal a

keen awareness of the potential of digitization at

those links in the value chain where the benefits are

most obvious. The highest scores were thus given to

the potential of digital data in the context of logistics,

as well as to automation in the context of production/

DIGITAL

TRANSFOR

MATION

THINK ACT

Digitization in the construction industry

6

WHICH AREAS HAVE THE MOST TO GAIN FROM DIGITIZATION?

Our survey shows that construction industry players do not see potential for digitization in all areas.

DEGREE TO WHICH DIGITIZATION IS ALREADY IMPLEMENTED

Little – or very little – has so far been done in most cases.

Across the same five areas, implementation is currently very sluggish indeed.

(1: very little or no implementation; <2: little implementation: >2: moderate implementation; >3: extensive implementation)

B

C

Logistics

Logistics

Procurement

Procurement

Production/

construction

Production/

construction

Marketing/sales

Marketing/sales

After sales/end-

customer marketing

After sales/end-

customer marketing

10

1.3

5

0.8

1

2.0

2

0.5

15

1.3

2

1.0

2

0.5

2

1.5

6

1.8

6

1.5

7

1.7

5

1.4

5

1.5

4

0.8

3

1.7

4

1.0

3

2.3

3

1.0

1

1.0

5

0.8

Source: Roland Berger

No. of mentions

Digital data Digital access Automation Connectivity Areas of potential

THINK ACT

Digitization in the construction industry

7

construction. Digital data and digital access were also

frequently mentioned in the context of marketing

and sales. On the other hand, procurement depart-

ments made little reference to the potential of digiti-

zation. Automation aside, respondents also saw little

potential for digitization in production settings. In

other words, there is a clear lack of awareness that all

four keys to digitization are of real importance

throughout the entire value chain.

B

The degree of across-the-board implementation

in the corporate community is correspondingly low.

Respondent firms were unable to name any division

or department in which digitization has already been

extensively implemented. Even "moderate" imple-

mentation currently only applies for connectivity (in

the context of procurement) and digital data (in pro-

duction). Cloud computing solutions for collabora-

tive production processes are one example. At all oth-

er links in the value chain, however, respondents

indicated that implementation is currently low, very

low or non-existent. The figure at right also shows low

to very low levels of implementation even in those ar-

eas where companies claim to recognize the potential

of digitization.

C

Looking at the digital devices used as work tools by

players in the construction industry, we see that, at

most companies, more than 80% of employees have

access to a PC and the internet. On the downside, there

is still a very sizable number of firms where the corre-

sponding figure is only between 20% and 40%. For

smartphones the picture is even more ambivalent.

Moreover, our survey clearly refutes the assumption

that tablets are already a standard tool among modern

players in the construction industry. At the majority of

respondent companies, no more than 20% have access

to a tablet. Not a single respondent claimed that more

than 60% of staff has access to a tablet. The image of

building workers organizing their work with tablets is

evidently still far removed from reality on today's

building sites. Yet precisely these devices and the apps

they contain hold out the promise of huge benefits, as

we will see later on.

D

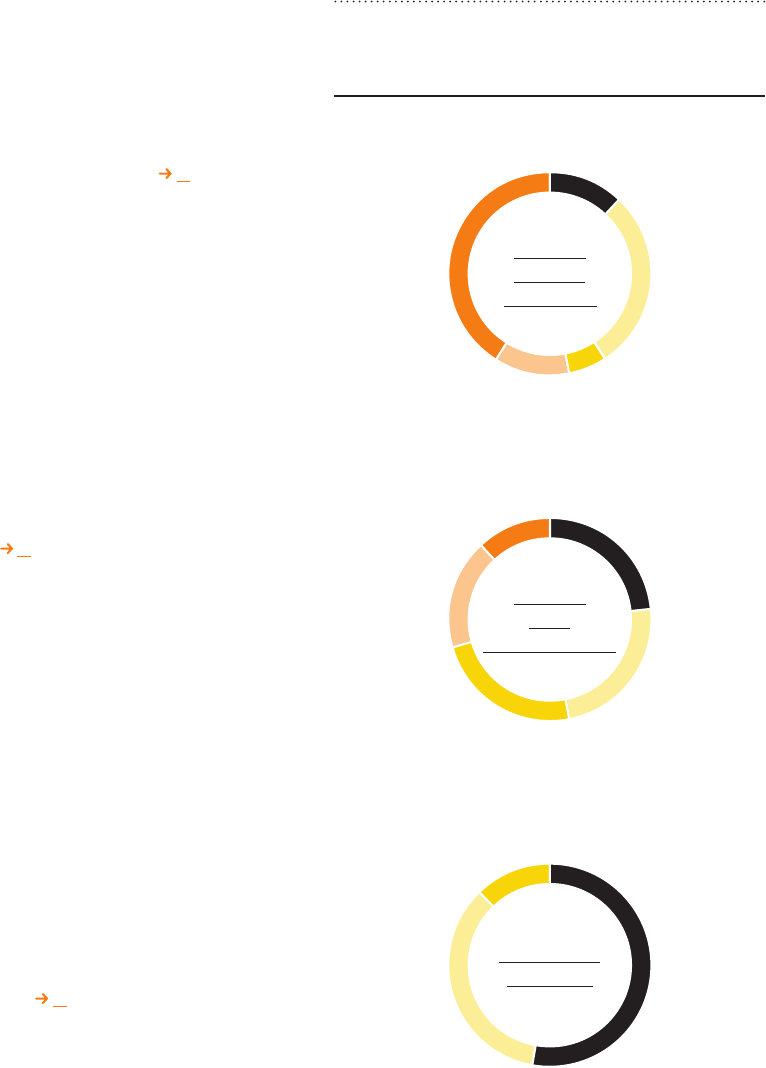

NOWHERE NEAR STANDARD ISSUE

Percentage of employees who have access to a PC/

the internet, a smartphone or a tablet.

D

12%

0 to under 20%

24%

0 to under 20%

53%

0 to under

20%

29%

20 to under

40%

24%

20 to under

40%

35%

20 to under

40%

41%

More than

80%

12%

More than

80%

6%

40 to under 60%

24%

40 to under 60%

12%

40 to under 60%

12%

60 to under 80%

18%

60 to under

80%

0%

60 to under 80%

Source: Roland Berger

No. of replies = 177

ACCESS

TO PC &

INTERNET

ACCESS

TO A

SMARTPHONE

ACCESS TO

A TABLET

THINK ACT

Digitization in the construction industry

8

The data in our survey testifies to an awareness that

digitization has an influence on the industry. The prob-

lem is that, in many cases, little has yet been done

about this realization. Above all, players in the industry

seem uncertain about how exactly to realize the bene-

fits of digitization at the various links in the value

chain. The following matrix reflects the diversity of the

methods and tools already in existence. Some of them

have a powerful influence on the business of construc-

tion companies and their suppliers; others have a mod-

erate to low influence. Some applications are already

established in business practice, while others are still

in the development phase.

E

Based on this matrix, we would highlight eight

technological developments and approaches that pow-

erfully affect the business of construction industry

players and whose degree of implementation is already

sufficiently advanced to yield genuine benefits. Our

recommendations include tools for every value chain

link and all market players.

1. ELECTRONIC TENDERING IS BECOMING

THE STANDARD

In Germany, calls for tender are already circulated elec-

tronically for 80 to 90% of public construction proj-

ects. The UK and Italy boast a figure of 100% for con-

tracts with volumes in excess of EUR 90,000. Standards

to ensure that tenders can be submitted securely and

in compliance with formal requirements are already in

place. At many construction companies, however, one

gets the impression that phones, fax machines and pa-

per are still the most widely used tools. That has to

change. Not as an end in itself, but because electronic

calls for tender are on the advance. The EU, for exam-

ple, insists on digital calls for tender for public con-

struction projects, because this channel ensures that

contract award processes are more transparent and ef-

ficient. Players keen to win public contracts who never-

theless refuse to wave goodbye to phones and fax ma-

chines will therefore very soon find themselves le

behind. Product specification too is increasingly going

digital. In this whole area, digitization has the added

advantage that electronic calls for tender reduce costs

while increasing efficiency. For construction suppliers,

the ability to contribute all products to planning pro-

cesses via digital channels – through a CAD library, for

example – will be a critical success factor. At the same

time, digital platforms are growing in significance for

building material traders.

2. DIGITAL PROCUREMENT PLATFORMS

SAVE TIME AND MONEY

Procurement and materials account for a large chunk

of total costs in the construction industry. Digital plat-

forms help keep these costs down. Electronic procure-

ment permits savings of around 5% for catalog-based

Recognizing potential

and seizing opportuni-

ties: How digitization

raises productivity.

THINK ACT

Digitization in the construction industry

9

E

TREND RADAR FOR THE GERMAN

CONSTRUCTION INDUSTRY

Our matrix reflects the diverse array of digital opportunities.

Source: Desk research, interviews, Roland Berger

After sales/end-customer marketingMarketing and sales

INFLUENCE ON BUSINESS

DEGREE OF IMPLEMENTATION

Customer

service

automation

Location-based

marketing

4PL

Buyer-side/

seller-side

e-procurement

Cloud-based

logistics platforms

Digital

storytelling

HighModerateLow

Emerging Developed Mature

Logistics Production/constructionProcurement

E-supplier

relationship

management

Additive

manufacturing

Robotics in

production

Analytics/

big data in

operation and

production

Human-machine

collaboration

Digital

content

marketing

PLM

Digital WMS

Augmented reality

in production

Predictive

maintenance

Cloud-based

logistics solutions

Field service

management

Augmented reality

in marketing

E-marketplaces

M-marketing

Analytics in customer service

Analytics/big data

in procurement

Automated

digital

marketing

Logistics management

software

M-com-

merce

Mobile logistics systems

Smart

MES

RFID

tracking

E-commerce

Analytics/big data in

marketing

Multichannel retail

CRM systems

Analytics/big

data in logistics

Social media

THINK ACT

Digitization in the construction industry

10

ready making good use of such electronic portals.

French company Saint Gobain is currently rolling out a

new digital logistics concept in Germany. Its aim is to

enable building sites to be supplied 24 hours a day,

which in turn gives industry players the chance to or-

der materials for very specific points in time.

4. DRONES AND ROBOTS MOVE OUT OF

SCIENCE FICTION BOOKS AND INTO THE

FUTURE OF CONSTRUCTION

Construction projects are becoming ever more

complex. Equally, cost and time pressures are rising

and quality expectations increasing. In response, the

industry must find ways to reduce complexity and

costs, raise productivity and guarantee quality. The

good news? The tools are already there!

Alongside advance planning, surveying the build-

ing land is one of the most important tasks in any

construction project. 3D laser technology opens up

new possibilities in this context. 3D lasers not only

survey the land, but also very quickly identify water

pipes, sewers, phone lines, fiber optic cables and pow-

er lines. They capture all this data and feed it into dig-

ital planning tools that are immediately available to

the project manager. Drones are likewise already in

operation in the construction industry. They survey

the land, monitor large building sites and track the

progress of construction projects. Where buildings

have been completed, they also measure energy dissi-

pation.

Mobile cloud solutions are growing increasingly

important in the building trade. Studies show that

communication occupies as much as 90% of construc-

tion project managers' time. When problems arise – if

different players don't have the same information or

can't access the data, for instance – the entire process

can quickly grind to a halt. As things stand, most build-

ing firms still use project management programs that

are installed on desktop PCs. Yet cloud-based and mo-

bile solutions have the tremendous advantage of being

available wherever you happen to be working. Here

again, it becomes apparent how much sense it makes

to work on site with mobile devices.

"Hadrian", the brainchild of Australian enterprise

Fastbrick Robotics, showcases what construction ro-

bots are already capable of doing. Buildings that would

have taken human brick layers several weeks to erect

can now be completed by Hadrian in 48 hours. The ro-

purchases and around 10% in the case of online auc-

tions, for example. Swedish construction outfit Skans-

ka does things differently, though, and already handles

about half of its material sourcing via a digital plat-

form. Tool manufacturer Hilti has outsourced all its

indirect procurement processes and now commissions

an external procurement management team to trawl

through catalogs, online shops and other electronic

platforms in search of the most attractive prices and

offerings.

3. SMART BUILDING SITE LOGISTICS

HOLDS OUT POTENTIAL FOR OPTIMIZATION

Construction workers devote only about 30% of their

working time to their principal activity. The remaining

70% is taken up by running errands, transporting ma-

terials, cleaning up, rearranging the building site and

looking for materials and equipment. It is therefore

perfectly understandable that many businesses see a

need for optimization.

This is where digital technology can help. Supply

soware, for example, can be used to ensure that mate-

rials are delivered to the site just in time, i.e. precisely

when they are needed. Storage and rearrangement

work can be minimized as a result. Similarly, smart,

connected construction machinery helps optimize ca-

pacity utilization for workers and construction vehicles

alike. Via the internet of things, excavators can call a

free truck whenever one is required. In return, the

truck can inquire when and where what material is

needed. Construction workers have fewer journeys to

make and less coordination work, so less time is spent

traveling and looking for things. Conversely this sce-

nario can only work if digital devices are standard issue

on the building site.

Apps are already on the market that use GPS or other

navigation technologies to locate products and materi-

als. RFID

2

technology in particular opens up all kinds of

possibilities. Products fitted with this technology can be

identified using electromagnetic fields. They can also be

registered and scanned, which simplifies the hiring of

equipment and creates transparency regarding the

whereabouts of machinery and materials on the build-

ing site. It is even possible to fit freshly laid concrete

surfaces with RFID technology in order to analyze them.

Soware solutions that help building firms with ev-

ery aspect of the logistical chain are also available.

Building material manufacturers in particular are al-

2 RFID = radio-frequency identification

THINK ACT

Digitization in the construction industry

11

bot is "fed" with 3D construction plans, in accordance

with which it trims, processes and lays each brick. The

benefits of this technology are obvious: Costs fall while

the quality of the "workmanship" increases.

3D printers are another digital innovation with a

bearing on the construction industry. One company in

China has already seized the opportunity: Following

the specifications of a 3D construction plan, it "prints

out" building parts that are made from a mix of rapid

hardening cement, industrial waste, rubble and glass.

The printing process takes two days for a three-story

building, slashing construction time by as much as

70% and manual labor by as much as 80%, as well as

saving up to 60% of materials. Since the process pro-

duces virtually no waste and reuses existing waste, it is

also kind to the environment. To service a major order

for more than 20,000 houses in Egypt, the Chinese firm

plans to use a sand-based mix. Its innovation thus

takes account of regional considerations, which fur-

ther improves efficiency. This development will also

have repercussions for building suppliers and building

material traders as it creates demand for the develop-

ment and production of innovative materials – and in-

novative trading companies.

5. BUILDING SUPPLIERS ARE LOOKING

TO DIGITIZE PRODUCTION

Alongside 3D printing on the building site, this tech-

nology can also be used to produce building materials

and construction products. Moreover, production in

general has brought forth many innovative methods

that have so far been largely ignored by makers of

building materials. Take logistics, for example: It is

very easy to integrate suppliers in digital data entry sys-

tems for purchase orders and for billing and quality

processes. On the product side, there is the chance to

develop new materials that feature high connectivity.

Production itself can be automated by the use of robots

to ensure that products can be extensively customized:

Input screens allow customers to specify the precise

products they want as soon as they place their orders.

High-quality production is monitored with the aid of

sensors, and high efficiency is, for example, guaran-

teed by energy-optimized production control based on

the order position.

The movement of products can be traced every-

where and at all times thanks to integrated RFID chips.

The production facility – and hence the logistics center

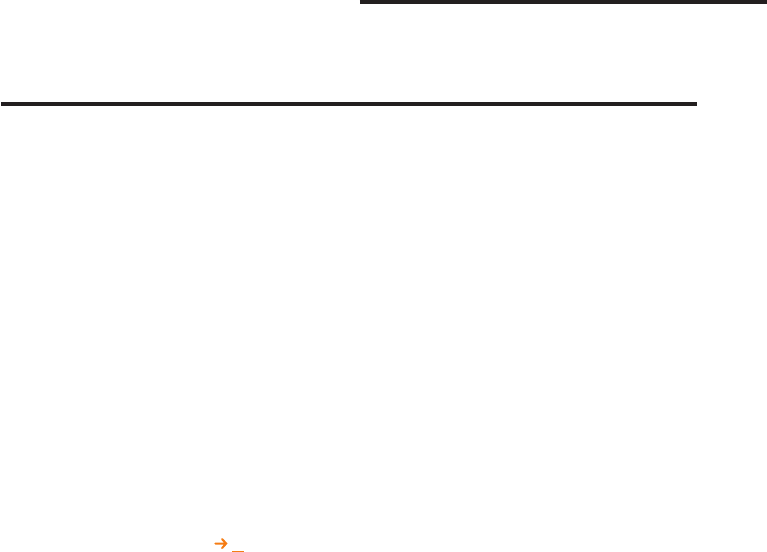

SALES FIGURES PROVE THE POINT: DIGITAL

WORKS FOR BUILDING MATERIALS TOO

Trend in DIY sales, 2006-2015 [EUR m]

F

Source: Statista, Results4retail

2006

24

2009

68

2011

110

2012

141

2013

165

2014

185

2015

212

+31% p.a.

THINK ACT

Digitization in the construction industry

12

2D

drawings

334

3D

models

329

BIM

3D

288

BIM

4D

7%

10%

4%

0%

6%

29%

58%

87%

87%61%38%13%

252

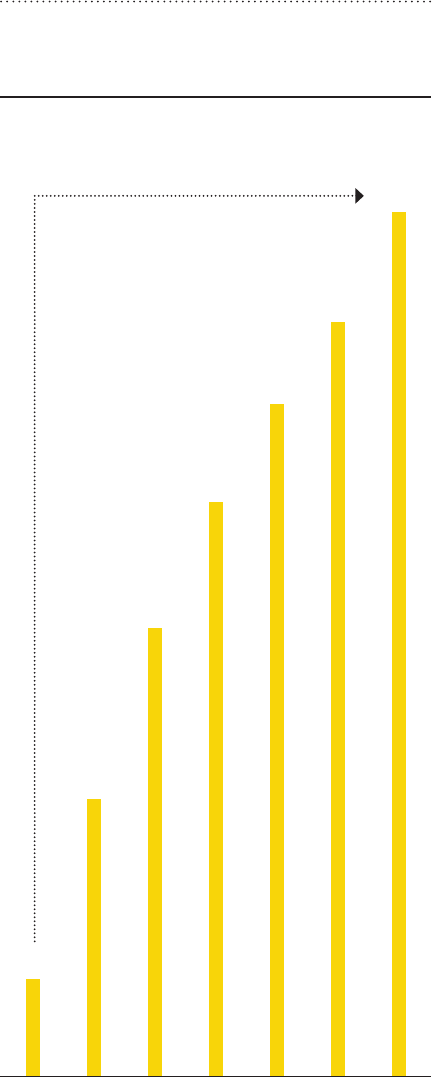

BUILDING INFORMATION MODELING (BIM)

Use of dierent planning methods in the construction

industry in 2015 [%]

G

Source: Fraunhofer Institute, Roland Berger

Planned for the future Always/frequent Never

too – is supplied by autonomous vehicles. A high-level

system controls and monitors the entire value chain.

This, then, is yet another area where construction in-

dustry players are recognizing the potential of digital

production ("Production 4.0"). But examples of exist-

ing implementations are few and far between. Perhaps

it would help the industry to take a look at other sec-

tors: In the auto industry, BMW is using collaborative

robots, while Airbus deploys robots and 3D printing

methods for production in the aircra industry.

6. DIGITAL SALES FACILITATES

MORE DIRECT SERVICE

Players in the construction industry benefit by knowing

earlier than their rivals what projects potential custom-

ers have in the pipeline and what the requirements will

be. Buying external digital data – from project databas-

es, for example – can give companies a head start in the

race for information about forthcoming projects. Digi-

tal solutions also help improve customer relationship

management by letting players analyze customer data.

Moreover, digital sales channels add the benefit that

customers leave a profile when they place orders via on-

line platforms. This profile allows patterns to be recog-

nized and tailor-made offerings to be prepared in re-

sponse. Online retailer Amazon shows the extent to

which these profiles can be used. And the enormity of

potential in the construction sector is reflected by de-

velopments in the DIY segment: Since 2006, online

sales here have jumped from EUR 24 million to EUR

212 million – an annual growth rate of just under 31%.

This is very definitely a forward-looking market.

F

In the context of communication with customers,

mobile apps make it possible to generate information

that is updated daily and is thus a perfect fit. That adds

value and cements customer loyalty. Insulation special-

ist Rockwool, for example, gives architects, crasmen

and building material traders an app that highlights po-

tential savings as soon as building data and current en-

ergy prices have been entered. It is not unusual for this

kind of service to convince customers immediately –

and trigger spontaneous purchase decisions.

7. WHEN YOU'VE DONE THE BUSINESS,

PREPARE FOR MORE

A number of special factors characterize relationships

between construction companies and their customers.

During a project, cooperation is intensive, but there

THINK ACT

Digitization in the construction industry

13

companies that fail to keep up in the area of BIM. 23%

"fully agree" and 45% "mostly agree" with the statement

that producers who do not provide BIM-compatible in-

formation will already fall behind in three years' time.

Construction firms themselves demonstrate far less

awareness of this danger, with only 15% "fully agreeing"

and another 15% "mostly agreeing". Obviously, players

in the construction industry must take care not to un-

derestimate the scope and importance of BIM.

As more and more planning is based on BIM, this

will probably lead to a shi in decision-making struc-

tures on the building site. Up to now, construction

companies and crasmen have sourced building mate-

rials from manufacturers of their choice in line with

specifications drawn up by planners and architects.

Soon, however, the planners and architects will also

decide quality issues and choose manufacturers. The

result will be hitherto unheard-of costing accuracy. Yet

at the same time, construction firms will evolve further

in the direction of pure-play contractors. BIM could

also shi construction activity from the building site to

industry. Building suppliers will seek to raise their pro-

file in BIM databases by providing end-to-end offerings

and system solutions. Accordingly, questions are even

being asked about the traditional three-tiered nature of

the German construction market itself. It is likely that

BIM will drive building suppliers' direct sales activities

onto the building site. The challenge to building mate-

rial traders will be to turn the opportunities afforded

by BIM to their own advantage and limit the growth of

direct sales.

The digital documentation required by BIM will

also cause the volume of product data to proliferate.

Construction firms have to be able to cope with the re-

sultant flood of data. Better still, analyzing this data

and putting it to profitable use will allow firms to ex-

ploit the full potential of this development. Buried un-

der all these piles of data is valuable information that

can lead to new business models or services.

are oen lengthy gaps between projects. This "down-

time" is exactly the right time to invest in long-term

relationships with customers. Digital aer-sales tools

that add value for and provide useful services to cus-

tomers are very useful in this regard. Building material

provider Cemex came up with Smart Silo, a product

that measures and communicates how much cement

is le in containers. The app ensures seamless supply

lines: New deliveries arrive just when they are needed

– and the customer doesn't have to li a finger.

8. BIM WILL SOON BE THE STANDARD

FOR EVERYONE ON THE BUILDING SITE

Building information modeling (BIM) is already tre-

mendously important to the construction industry. A

2014 EU directive recommends the use of BIM use as

one of the criteria for the award of public contracts.

The multiphase plan "Digital Planning and Construc-

tion launched by Germany's Federal Ministry of Trans-

port and Digital Infrastructure on December 15, 2015,

follows the directive's lead and makes the use of BIM

compulsory for public infrastructure projects in Ger-

many as of 2020. Similar rules already apply in the UK,

the Netherlands, Denmark, Finland and Norway.

According to a study by the Fraunhofer IAO insti-

tute, however, only 29% of players in the German con-

struction industry today use BIM as an object-oriented

building model (3D), although 10% at least plan to do

so in future. 4D BIM, which incorporates time as an

additional planning dimension, is used only by 6% of

players, while 7% plan to introduce it.

G

Clearly, the industry does not recognize the poten-

tial of BIM. The big advantage of this method is that a

digital simulation of the project is created before the

first brick is laid. BIM thus minimizes planning errors,

permits fast calculations, quantifies extra costs and

shows alternatives.

A lack of BIM expertise could therefore become a

serious competitive drawback in the near future, al-

though players in the construction industry are of a

different opinion: Only 31% of the study respondents

agree that producers who fail to supply BIM-compati-

ble information will be at a severe disadvantage three

years from now. A far higher proportion of architects

– 68% – agreed with the same statement.

A recent construction industry study by Roland

Berger and HypoVereinsbank also shows that many ar-

chitects expect there to be negative consequences for

THINK ACT

Digitization in the construction industry

14

The profound impact of digitization will thus be felt

throughout the entire construction industry. Which-

ever angle you take – the competitive situation or pro-

ductivity considerations – companies have no choice

but to tackle this vital issue.

Those companies that move early to develop and

implement their own digitization strategy will be the

winners as the construction industry goes digital.

The "construction firms of the future" will use dig-

ital tools to have materials supplied just in time, there-

by cutting the cost of storage and transportation and

increasing efficiency. They will source materials with

electronic portals and, in so doing, optimize not only

their prices but also their collaboration with suppliers.

In production, building suppliers will deploy smart

machinery and applications that forge networks in

which all production processes are planned in advance

and operated with optimal efficiency. In marketing

and sales, they will win over dealers and customers

with digital sales applications. In aer-sales, they will

provide customers with new service and support that

increases customer retention.

Building material traders will operate efficient plat-

forms that add transparency while also making their

customers' processes more efficient. At the same time,

they will harness the data generated to gain a better

understanding of their customers and produce cus-

tomer profiles.

The possibilities opened up by Construction 4.0 give

players in the construction industry all kinds of ways

to boost their productivity. A glance at other industries

shows that these new approaches and tools do indeed

affect every link in the value chain. Depending on their

maturity, size and business model, digitization thus

holds out potential for every corporate group in the

German construction industry.

We have identified four keys to unleash the poten-

tial of digitization: digital data, digital access, automa-

tion and connectivity. And each of these keys can be

turned at each link in the value chain: in logistics, pro-

curement and production, in marketing and sales, and

in aer-sales and end-customer marketing.

Companies face the challenge of deciding which

approaches suit them best and how they can be imple-

mented. Ignoring digitization entirely is not one of the

options. Recent developments in construction and

other branches of industry show that there is no stop-

ping the megatrend toward digitization.

It follows that players in the construction industry

who move quickly to concern themselves with techno-

logical developments and think carefully about how to

implement them all along the value chain have every

chance of setting themselves apart from the competi-

tion. By introducing digital methods, these firms will

become more productive and more effective.

On the other hand, companies that ignore the keys

to digitization run the risk of falling behind their rivals.

One reason will be the loss of business. Another will be

that they cannot improve their productivity as they

would like to.

Bottom line:

Ignoring digitization

is a mistake.

15THINK ACT

Digitization in the construction industry

GOING DIGITAL – A NEW ALLIANCE

FOR THE INTERNET

In collaboration with Roland Berger,

the Internet Economy Foundation

IE.F has developed an action plan for

successful digital transformation in

Germany and Europe. The plan covers

finance, infrastructure, competition,

data protection, governance, digital

literacy and the business culture. One

central finding of the study: Young

German businesses will need growth

capital of approximately 50 billion

euros in the next five years to take

advantage of digitization

opportunities for Germany.

CONSTRUCTION INDUSTRY

IN TRANSITION. TRENDS AND

POTENTIAL THROUGH 2020

The German construction industry

has been growing steadily for a

number of years. Current develop-

ments such as the influx of refugees

and trends such as the digitization of

industry and the need for efficiency

gains are putting further wind in the

sails of the German market. Yet they

also confront construction with

major challenges: Flexible business

strategies need to be found if the

positive development of recent years

is to continue. This is the finding of

a new study by Roland Berger and

HypoVereinsbank (HVB).

ABOUT US

FURTHER READING Links&Likes

ORDER AND DOWNLOAD

www.rolandberger.com

STAY TUNED

www.twitter.com/

RolandBerger

LINKS AND LIKES

www.facebook.com/Roland

BergerStrategyConsultants

A detailed insight into

current thinking at

Roland Berger is available

via our new microsite at

new.rolandberger.com

Roland Berger, founded in 1967, is the only leading global

consultancy of German heritage and European origin.

With 2,400 employees working from 36 countries, we have

successful operations in all major international markets. Our

50 oices are located in the key global business hubs. The

consultancy is an independent partnership owned exclusively

by 220 Partners.

TA_16_019

Publisher

ROLAND BERGER GMBH

Civil Economics, Energy & Infrastructure

Competence Center

Sederanger 1

80538 Munich

Germany

+49 89 9230-0

www.rolandberger.com

Editor

DR. KATHERINE NÖLLING

katherine.noelling@rolandberger.com

DR. KAISTEFAN SCHOBER

Partner

+49 89 9230-8372

kai-stefan.schober@rolandberger.com

DR. PHILIPP HOFF

Principal

+49 69 29924-6193

philipp.ho@rolandberger.com

This publication has been prepared for general guidance only. The reader should not act according to any

information provided in this publication without receiving specific professional advice. Roland Berger GmbH

shall not be liable for any damages resulting from any use of the information contained in the publication.

© 2016 ROLAND BERGER GMBH. ALL RIGHTS RESERVED.

WE WELCOME YOUR QUESTIONS, COMMENTS

AND SUGGESTIONS